Micro-nano fabrication and characterisation of materials

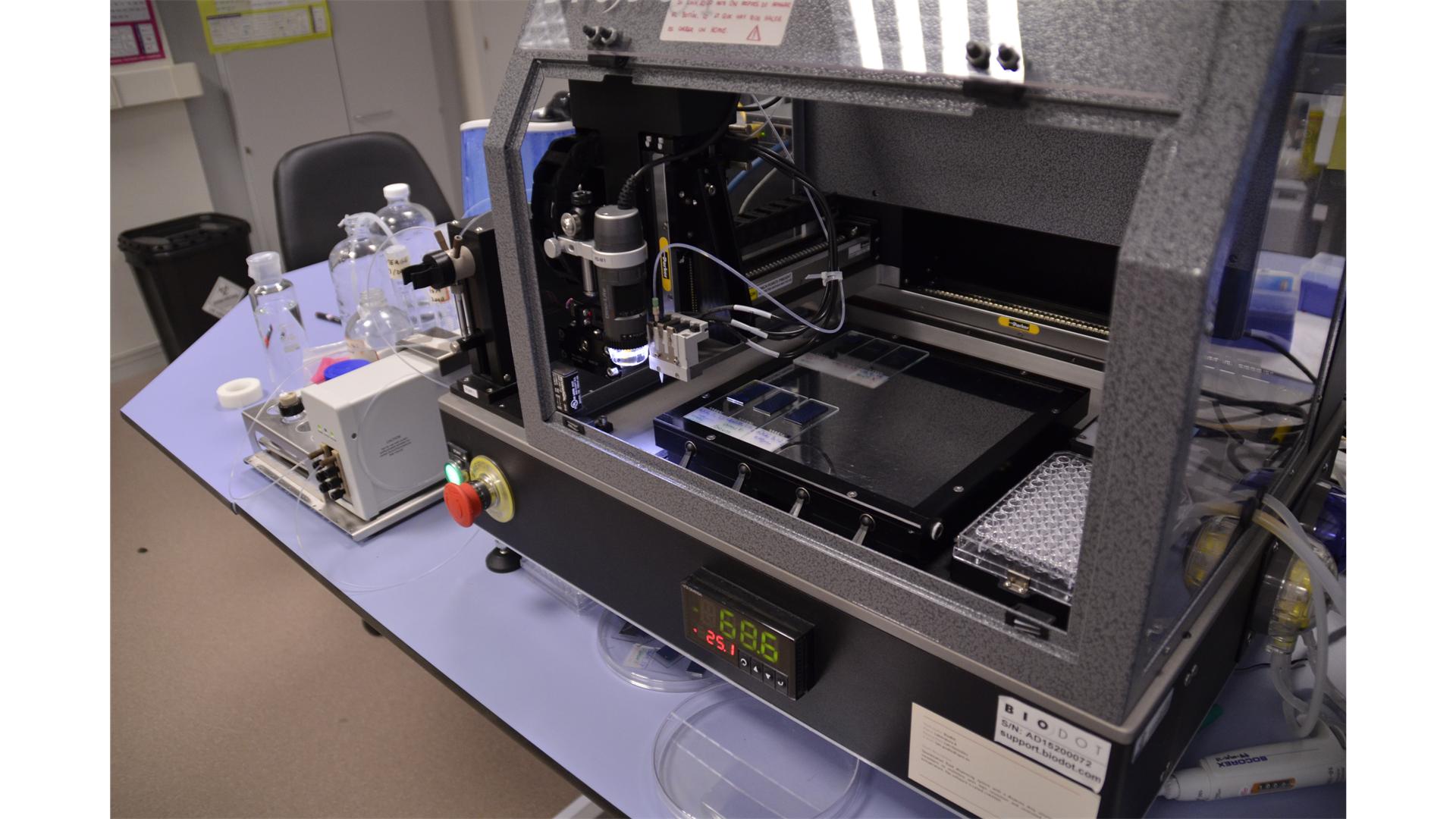

NANO AND PICO VOLUMEN DROP DISPENSING

Automatic deposition of liquids in extremely low volumes (nano and picolitres) in a modular and configurable way.

Contrato financiado mediante el CONVENIO ENTRE LA COMUNIDAD DE MADRID (CONSEJERÍA DE EDUCACIÓN, UNIVERSIDADES, CIENCIA Y PORTAVOCÍA) Y LA UNIVERSIDAD POLITÉCNICA DE MADRID PARA LA CONCESIÓN DIRECTA DE UNA AYUDA DE 7.912.000,00 EUROS PARA FINANCIAR LA REALIZACIÓN DE ACTUACIONES EN MATERIA DE INVESTIGACIÓN SOBRE EL SARSCOV2 Y LA ENFERMEDAD COVID-19 FINANCIADO CON LOS RECURSOS REACT-UE DEL FONDO EUROPEO DE DESARROLLO REGIONAL.

Fabrication

ADVANCED SURFACE BIOFUNCTIONALIZATION

Surface functionalisation of biomaterials by AVS (Activated Vapour Silanization) technique.

Fabrication

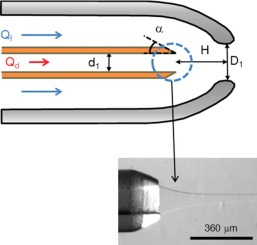

HIGH-PERFORMANCE BIOCOMPATIBLE FIBERS

Production of biocompatible fibres with high mechanical performance and controlled properties for use as structural biomaterial in tissue engineering by SFS (straining flow spinning) technique.

Fabrication

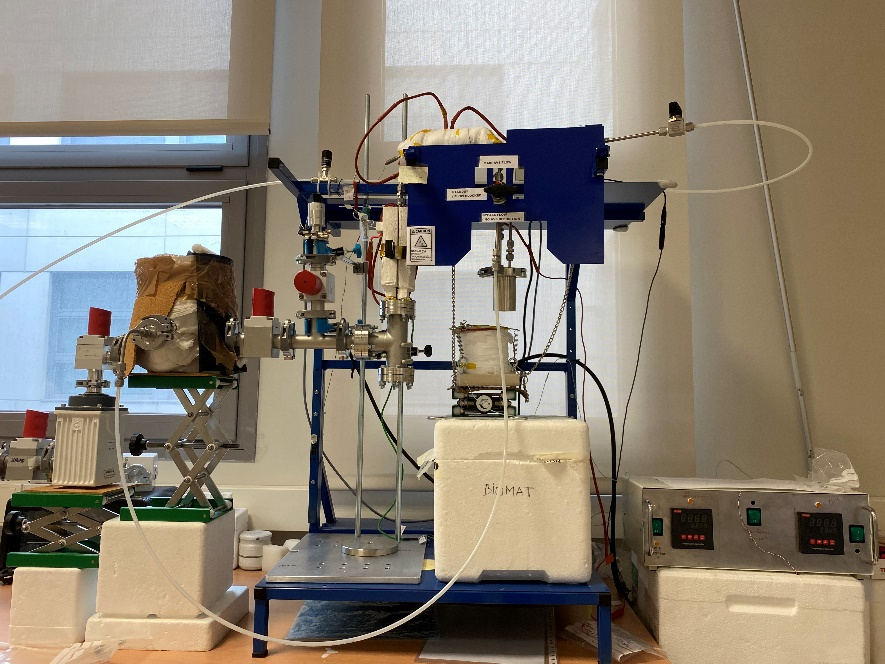

NANOROBOTICS EQUIPMENT

Tests of magnetic field application in different circumstances evaluating the damage produced in the cells by cell viability analysis.

Fabrication

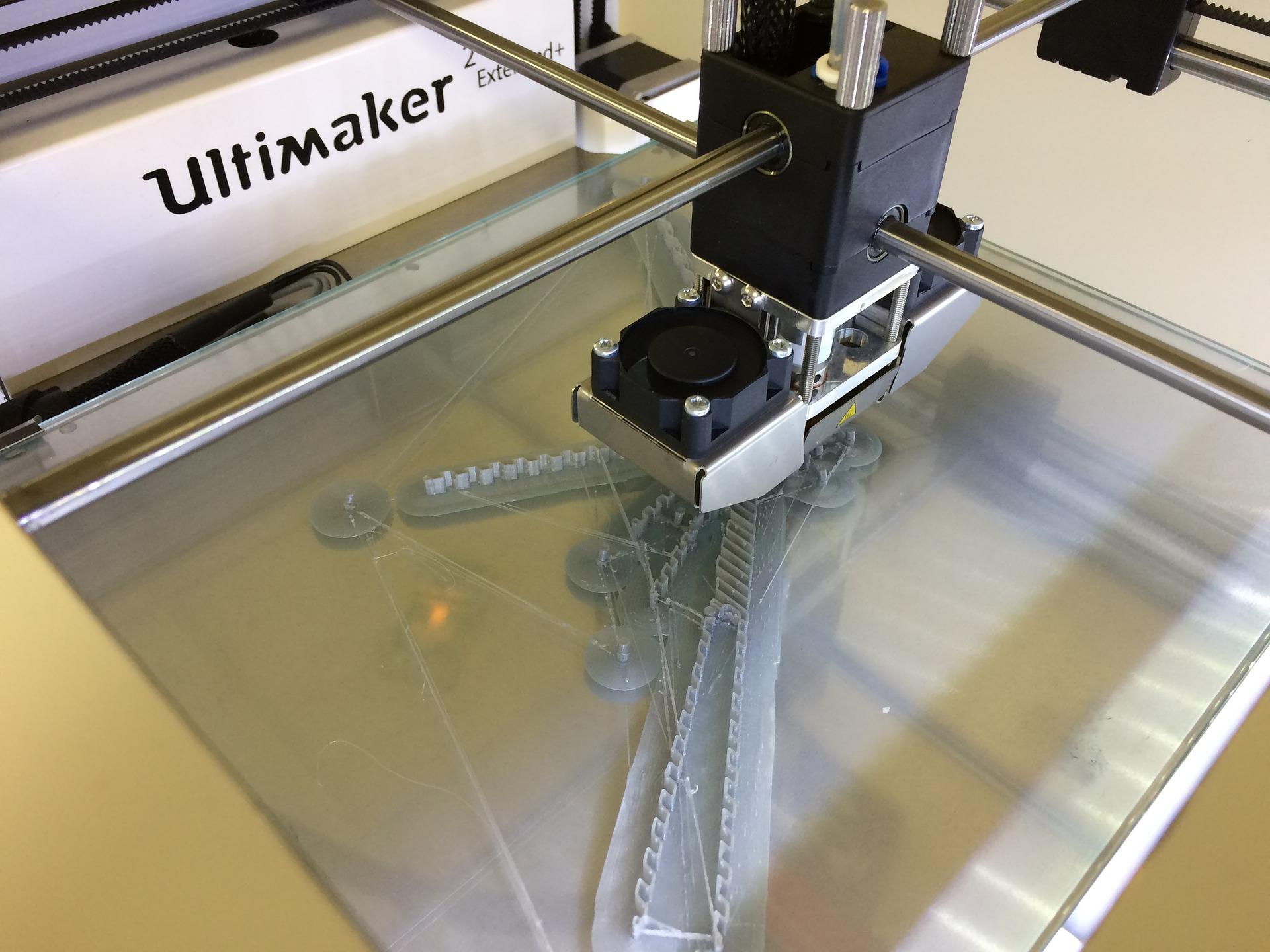

3D PRINTING

Mechanical design and prototyping of three-dimensional solids.

Fabrication

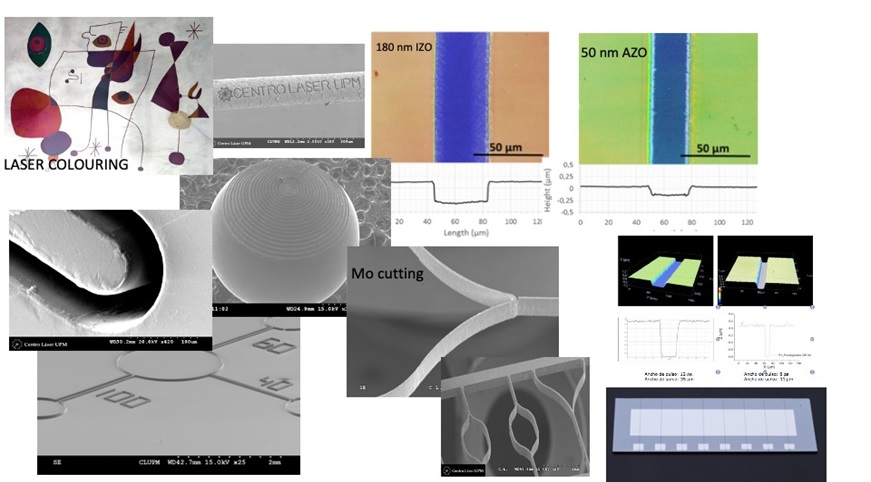

LASER MICRO AND NANO MANUFACTURING SERVICE

Study, parameterisation and execution of laser processes with dimensional tolerances in the micro and sub-micrometric range in any type of material.

Fabrication

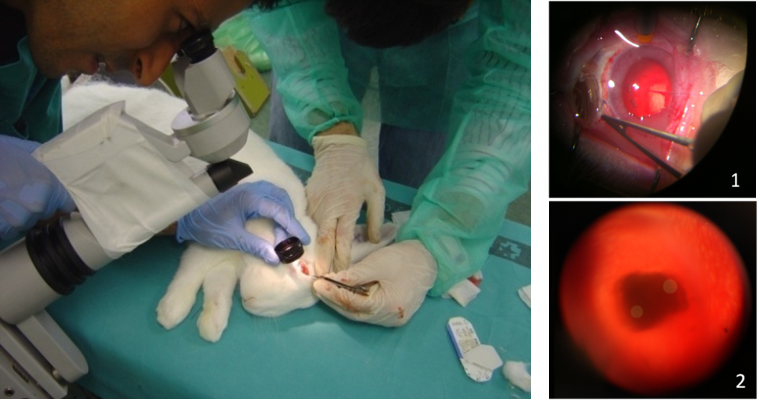

LASER BIOPRINTING

Printing of cellular material for development of in vitro models of immune response, enhancement of tissue engineering models, and single cell isolation in different biomedical fields.

Fabrication

LIFT AND HYBRID MICRO-MANUFACTURING LABORATORY

Laser Induced Forward Transfer (LIFT) direct writing processes for additive laser printing and surface modification processes.

Fabrication

LASER CUTTING, WELDING AND ADDITIVE MANUFACTURING STATION

Laser macro processes: marking, cutting, welding, surface treatments, shaping and additive manufacturing.

Fabrication

MECHANICAL PROPERTIES CHARACTERISATION LABORATORY

Characterisation of the mechanical properties of laser-processed samples, analysis of the changes produced and parameterisation of new laser processes for aeronautics, automotive and energy applications.

Fabrication

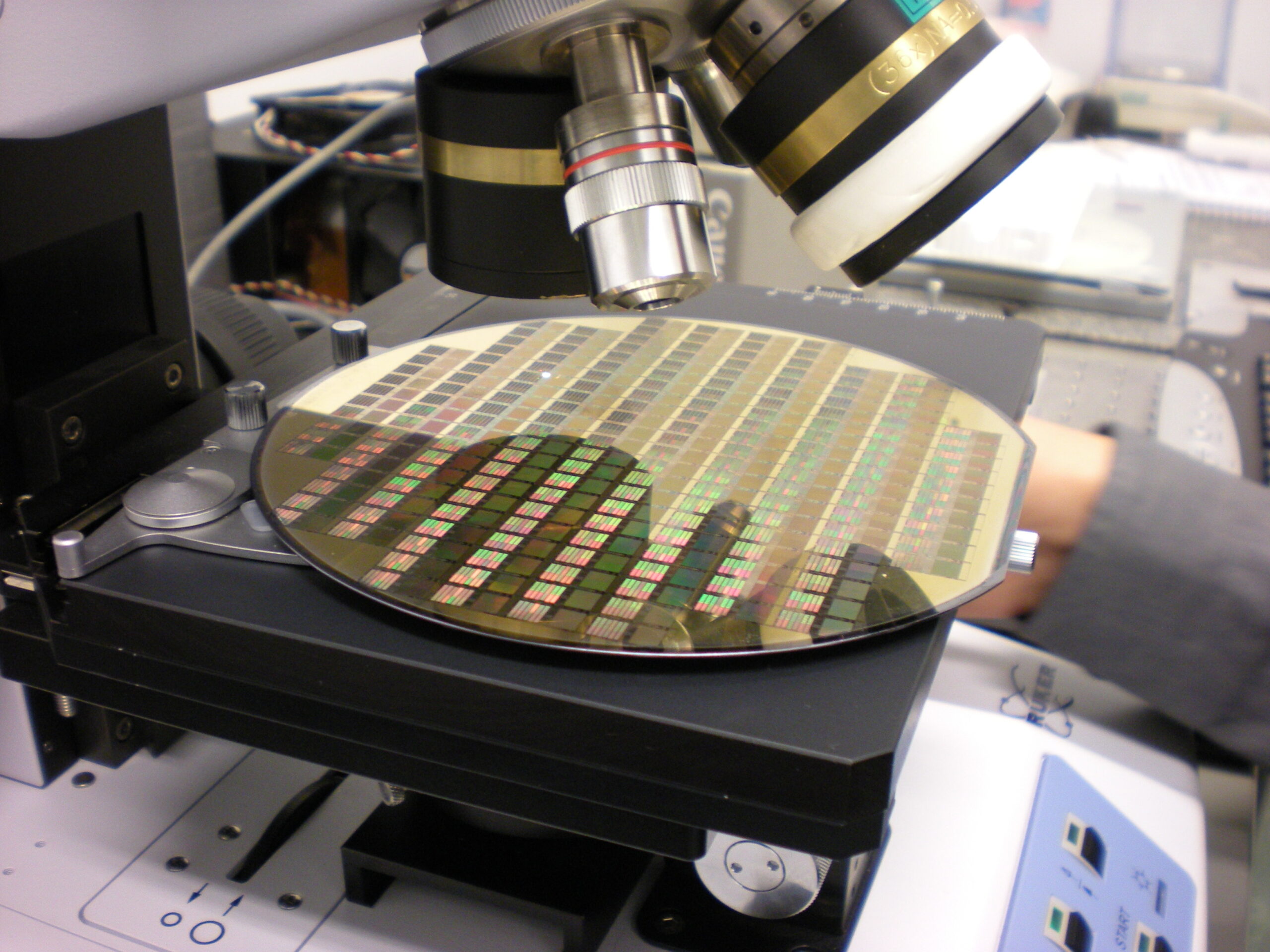

UV MASK ALIGNER PHOTOLITHOGRAPHY

Nano and micro fabrication by mask aligment photolithography technique for ultraviolet-sensitive photoresists.

Fabrication

THIN FILM MANUFACTURE

Manufacture of thin films of micro and nanometric dimensions using the spin coating technique for deposition on liquid materials: resins, photoresins, polymers.

Fabrication

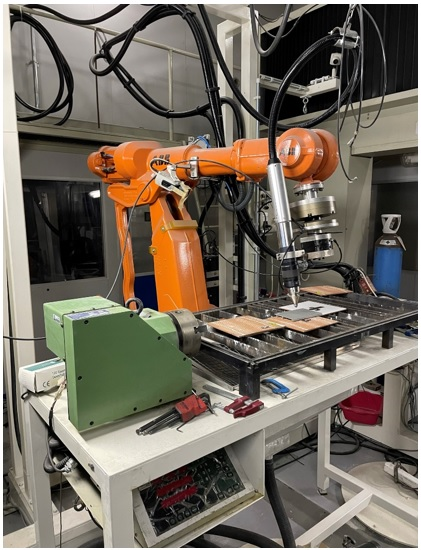

MICRO VOLUME DEPOSIT USING CNC

Contactless, automated and accurate deposition by a numerical control robot of liquid volumes in the nanolitre range.

Fabrication

OXYGEN PLASMA TREATMENT

Generation of oxygen plasma at low pressure to break molecules into volatile compounds for removal of organic compounds from the surface of materials, disinfection, and activation of the OH groups of oxidised surfaces.

Fabrication

DYNAMIC VISCOSITY CHARACTERISATION IN BIOLOGICAL FLUIDS

Real-time measurement and monitoring of viscoelastic properties of synovial and cerebrospinal fluid.

Characterisation

ELECTROMECHANICAL TEST FOR BIOLOGICAL MATERIAL

Mechanical tensile, compression or bending tests for characterisation of biological materials and biomaterials, such as blood vessels, tendons, membranes, hydrogels.

Characterisation

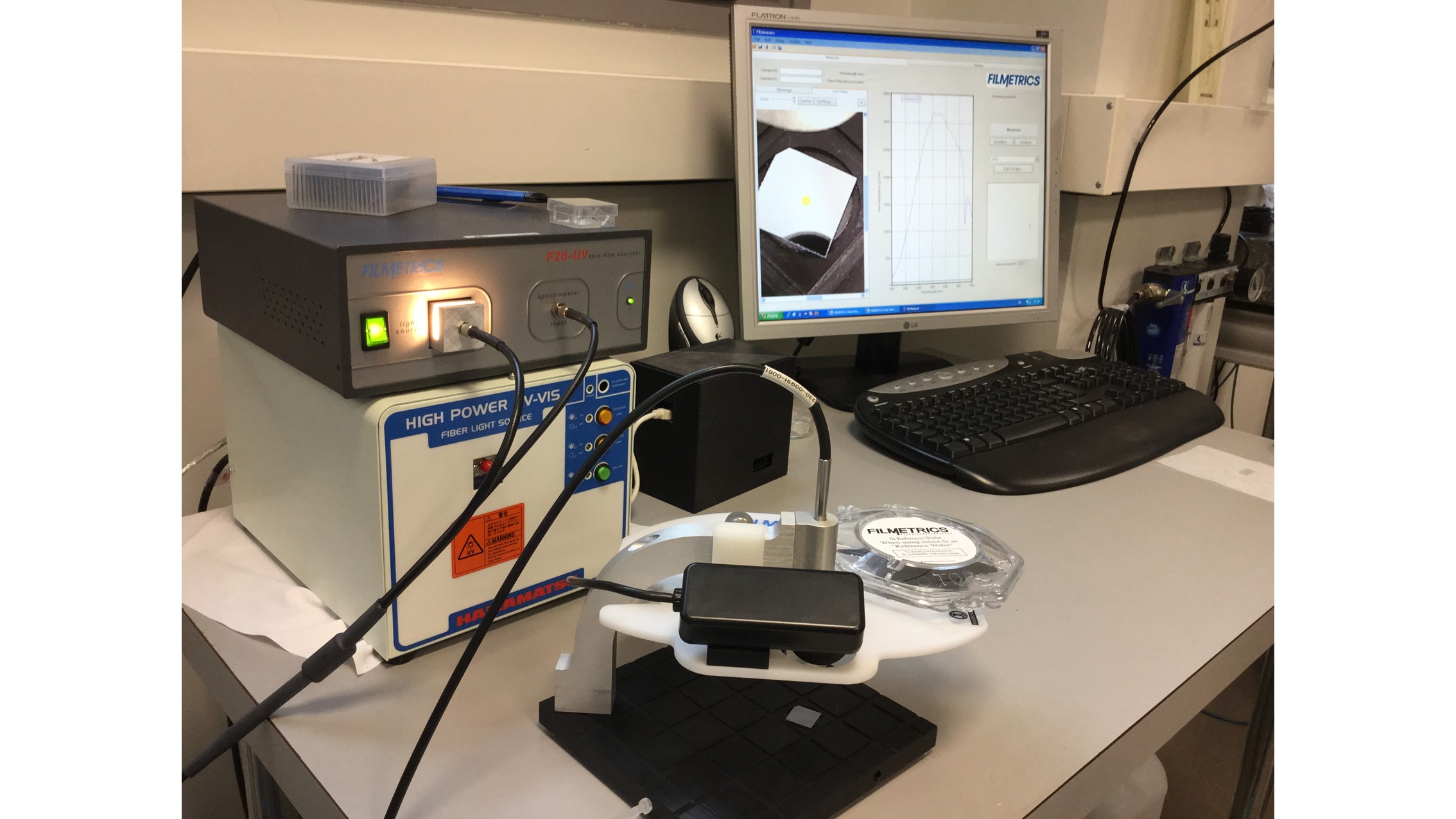

THICKNESS MEASUREMENT AND OPTICAL CHARACTERISATION

Optical characterisation for halogen lamp measurement of thin film thickness and refractive index.